3D Printer Beginner FAQs

Dear Readers, I’ve recently embarked on a new journey / hobby of 3D printing, here’s my story.

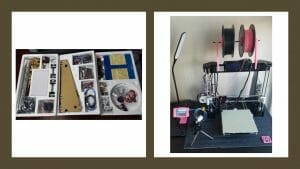

I started by researching 3D printers on YouTube. I found copious amounts of resources on 3D printing from assembly, tips & tricks, maintenance, and suggested uses. The first thing that struck me was that most 3D printers come un-assembled and require anywhere from 5-11+ hours to put together. Next, is the calibration process. The table that the 3D printer sits on needs to be perfectly level and then the print bed must be adjusted to 0.02mm from the extruder (equivalent of a print head on a traditional printer).

Caption: Anet A8

Assembly and calibration was just the beginning of my journey.

Below is a compilation of the most Frequently Asked Questions from my friends and family about my new hobby.

What kind of paper, toner, and/ink do you need for a 3D Printer?

Instead of paper and toner, you need filament for a 3D printer. The most common type of filament is PLA, which is a plastic that is heated to about 200° Celsius and then squeezed through an “extruder,” like an expert baker decorating a cake with frosting.

How Hot is Hot?

The PLA is melted by the extruder that is set to a temperature between 190° to 210° Celsius. 200° Celsius is about 410° Fahrenheit.

Is a 3D printer a fire hazard?

YES! There have been documented cases of mis-wiring or faulty power supplies that have sparked fires.

Can I “set it and forget it”?

No, at minimum you need to watch the first layer – getting a good first layer is key to a good print, and then check on it every 30 minutes or so.

It’s all about the MODs

Modifications, that is.

What was my first 3D print?

My first print was technically a ‘test print’ of a circle inside a square to test my calibration. Real exciting, huh?

My first real print was a cooling ring. Assembled, the 3D printer made an awful whistling sound as the cooling mechanism in the kit (also 3D printed) actually looked like a whistle.

No joke. Almost every ‘beginner’ video I watched on YouTube advised me to replace the “whistle” with a printed cooling ring. Once I replaced the cooling mechanism, with my 3D printed cooling ring, the loud whistling sound disappeared. Why don’t they just include the non-whistle cooling ring in the assembly kit? No idea, but it doesn’t stop there.

I also printed a filament spool insert, so that the filament would spin off the reel evenly.

Why is this not out-of-the-box functionality? No idea. It should be.

The printer isn’t assembled when all the pieces from the box are put together. You have to continue to print additional pieces of the printer. Printing a new cooling ring and filament holder is just the beginning. I also saw numerous reinforcement and stabilization printed parts.

Do you wirelessly print to a 3D printer?

Out-of-the-box, No. The 3D printer has uses a typical wired USB cable so that you can print directly from your computer to the 3D printer. More common is to save the print files to a microSD card, and then insert the microSD card into the printer. The printer has an LCD screen and 5 buttons to navigate and print.

But, you can connect a Raspberry Pi to the printer, install OctoPrint software, which essentially turns your 3D printer into a wireless printer.

I found excellent resources that stepped me through the process easily.

- Gather all required materials: Raspberry Pi (I used an RPi3), Touch Screen for RPi3, Webcam, keyboard.

- Print out a Raspberry Pi case and stand.

- Install OctoPrint software on the Raspberry Pi.

- Connect your USB webcam to the Raspberry Pi and enable webcam.

- Download the OctoPi app to your iPad or iPhone. (I could not find an equivalent app on Google Play…yet)

- Open the web browser on your computer and navigate to the IP address:5000 to access your printer.

How do you find stuff to print on a 3D printer?

I started by google searching “stuff to print on 3D printer” and came across a great blog article with links and pictures of great starter 3D printing projects. Most of the links pointed to a website called Thingiverse.com. There are literally thousands of pre-made projects available for free download on Thingiverse.com

According to this video by Maker’s Muse, Yoda is one of the most popular 3D prints available. Here’s my Yoda bust.

These free designs are great, but how do I design my own?

There are a variety of programs to design your own items. I found free cloud software called Tinkercad that allows you to create your design directly on their website and then download your design as an STL file. Another website where designers can collaborate is 3DOrchard. I learned about 3DOrchard at Atlanta Maker Fair in October. Video from 2017 Atlanta Maker Faire here.

Once I have a file, what is the process to actually print it?

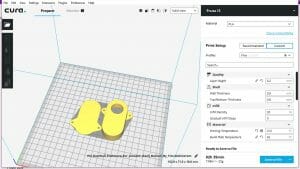

Cura is a free software package that takes STL design files, slices (converts the design file), and can save as the file your 3D printer actually uses.

3D printing has been around for a while now. As I mentioned previously, there are literally thousands of available designs to download. Design can be done in the cloud. OctoPrint on a Raspberry Pi with a webcam is almost ‘pedestrian’ at this point. I will admit that most of the YouTube videos I watched to learn about 3D printing were from Europe and my entire 3D printer was created on the basis of the metric system. Does that mean that 3D printer is more prevalent in Europe than the US? Please feel free to comment below and let me know your thoughts.

So far, I am genuinely enjoying my new 3D printer. By assembling the printer myself, I know where all of the motors are located and how they work. I know how to calibrate my printer and adjust settings in Cura for optimal prints. As a beginner, I’ve mostly printed ready-made designs by others. As I learn more, I will transition to custom designs. Perhaps I will make a Wireless Technology Forum branded phone cover or prototype my next invention?

If you’re interested in learning more about 3D printing, but don’t want to invest 6-11+ hours of your life assembling a 3D printer, I suggest you check out the classes at MODA where you can print your own object.

MODA 3D printing classes – http://www.museumofdesign.org/hands-on-design/

Time Lapse of my 3D printer assembly and Yoda bust print.